Clean Room Hvac Design Calculations

Cleanrooms and hvac systems design fundament.

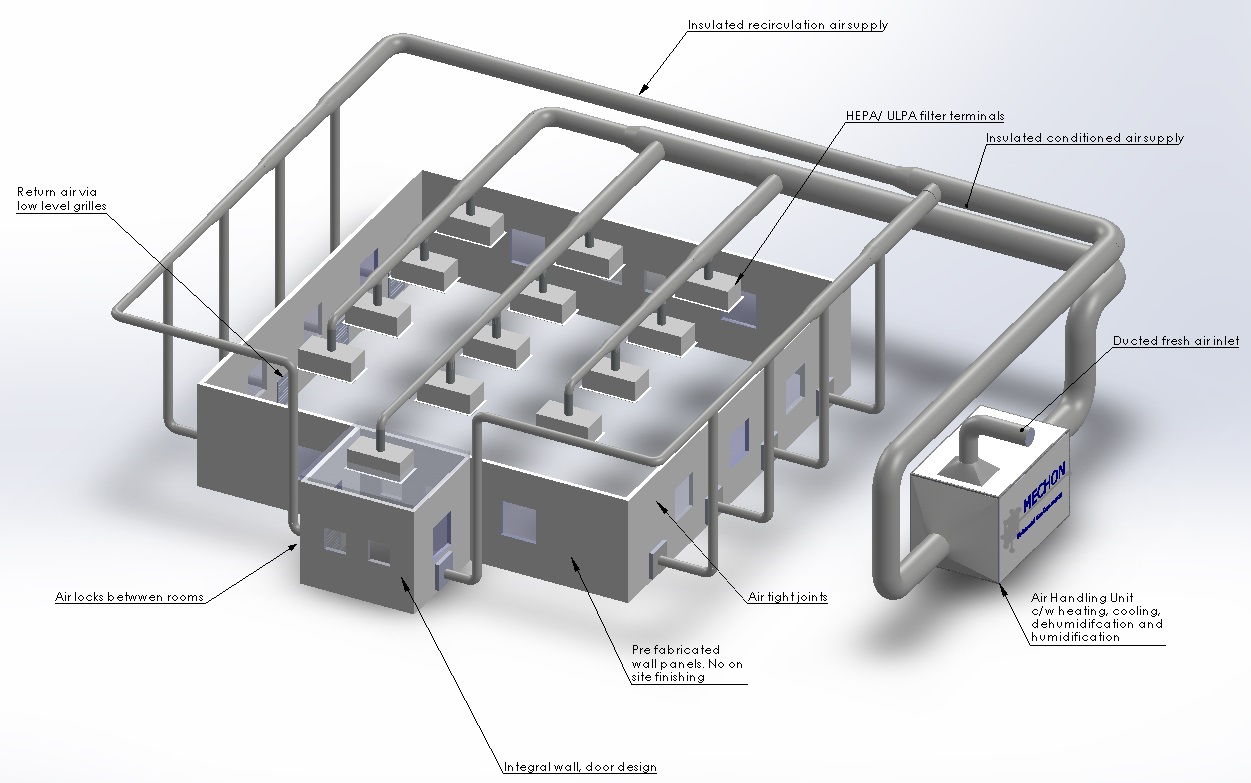

Clean room hvac design calculations. Ashrae clean spaces technical committee tc9 11 chairman 07 10 healthcare facilities technical committee tc9 6 member laboratory systems technical committee tc9 10 member iest working group cc012 cleanroom design chairman president. A lot of aspects are not taken into consideration for the calculation including but not limited to heat gain number of people the use of a fume hood etc. The above suggested air changes per hour are only a design rule of thumb. Supplying airflow in sufficient volume and cleanliness to support the cleanliness rating of the room.

The width length and height of the classified rooms and their layout must be used for hvac calculations. The width length and height of the classified rooms and their layout must be used for hvac calculations. Calculations should be computed by a cleanroom hvac specialist. If you want help with the design of your cleanroom fill out a request for quote and one of our experts will contact you.

They should be computed by an hvac cleanroom expert as many aspects must be taken into consideration such as the size of the room the number of people in the room the equipment in the room the processes involved the heat gain etc. Hvac systems design fundamentals karachi pakistan february 22 2011 wei sun p e. If the supply of the air by hvac system in one hour is equal to the volume of the room then it will be one air change per hour. The bigger the room the more air you need.

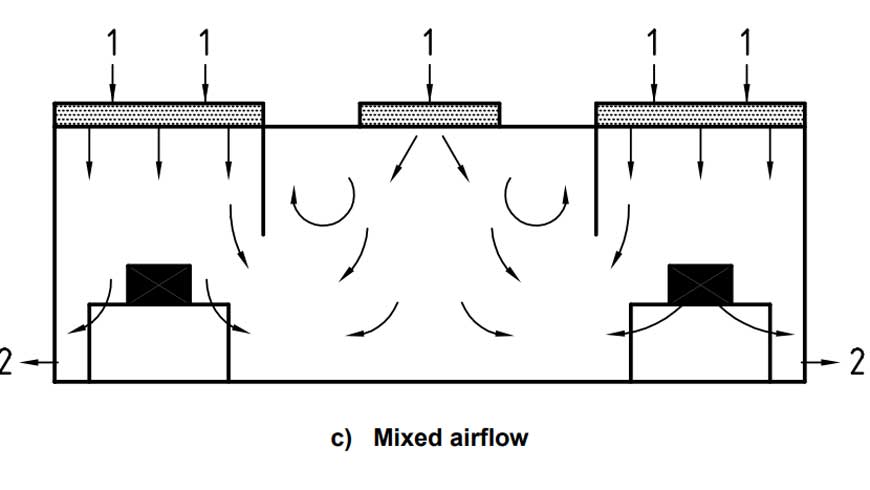

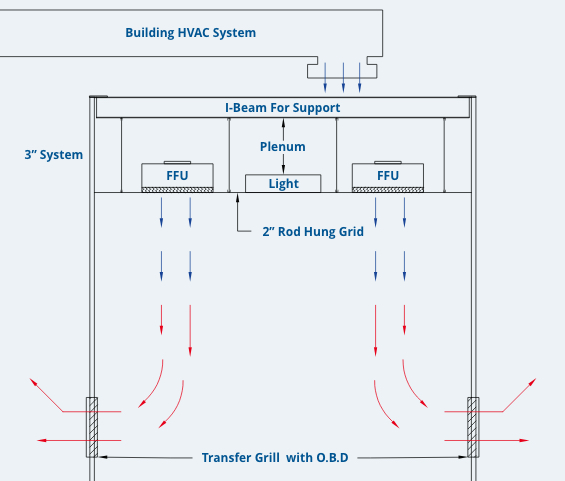

The volume of air in the cleanroom will influence the amount of airflow needed. Design of the ventilation system shall provide air movement which is generally from clean to less clean areas. 2 the hvac system the integrity of the cleanroom environment is created by the pressure differential compared with adjacent areas through heating ventilation and air conditioning system. The hvac system requirements include.

People often forget that the height of the room directly impacts the airflow. Fda recommends maintaining the minimum 20 air changes per hour for clean rooms. People often forget that the height of the room directly impacts the airflow. The bigger the room the more air you need.

If any form of variable air volume or load shedding system is used for energy conservation it must not compromise the corridor to room pressure balancing relationships or the minimum air changes required by the table. This is achieved by supplying more air to the room than is extracted from it. The volume of air in the cleanroom will influence the amount of airflow needed.